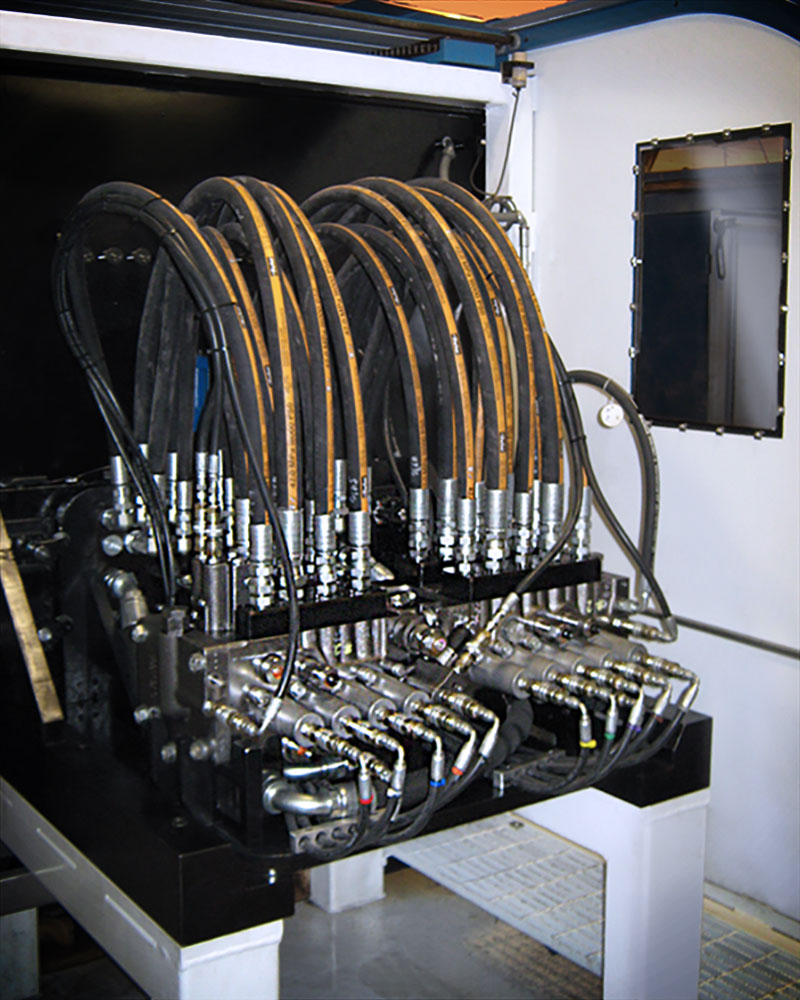

Hydraulic Excavator Main Control Valve

The facility is based on a closely integrated production and testing layout. It includes an external leak detection system and a material handling/fixture system for production testing of the specific models. The material handling system utilizes electric pallet stackers with special fixtures that allow the test valve to be connected automatically when the stacker is driven into the test station. The test stands include two stations, one for internal leakage checks, a second for performance testing.

The hydraulic system, instrumentation and control system and the primary software are all proven REN CORPORATION designs. The proposed system is sufficiently robust to accommodate any foreseeable changes in the test procedures or product configuration without extensive modification.

The instrumentation and control system is housed in a separate enclosure connected to the standby a wiring duct which isolates sensitive instrumentation from the high power noise inducing components. The electrical enclosure(s) which contain the high voltage switchgear and controls will be integrated into the test stand structure.

Each test stand is constructed in three major sections, which are separated for shipment in standard ocean containers. The base of each section will be configured as a weldment of structural steel and plate which supports the pump and motor assemblies on anti-vibration mounts. Each base structure is seal welded.

The work area is configured to be serviced by a single operator. The latest REN shield design configuration (shown above) offers a practical solution to the problem of providing both operator protection and easy access for installation and adjustments

This stand features a complete oil conditioning system with cooling and filtration, a pilot pressure supply pump and a drain return system.

The leakage supply will use conditioned oil from the circulation system routed through a small chiller system to maintain the required leakage oil temperature of 27 ºC (81 ºF). The chiller is included in the test stand. A fixed displacement pump operating in an open loop circuit supplies the specified pressure for the leak tests.

The auxiliary pilot pressure is supplied by a variable displacement, pressure compensated vane pump. This supply will be used for any auxiliary functions such as fixture clamps, shield operation, etc.

This is one of several test stands of this type supplied to this client and is currently used for production.

Project Details

DATE

March, 2011

CLIENT

Caterpillar

COMPONENT

Valve