Truck Cylinder Test Stand & Assembly Facility

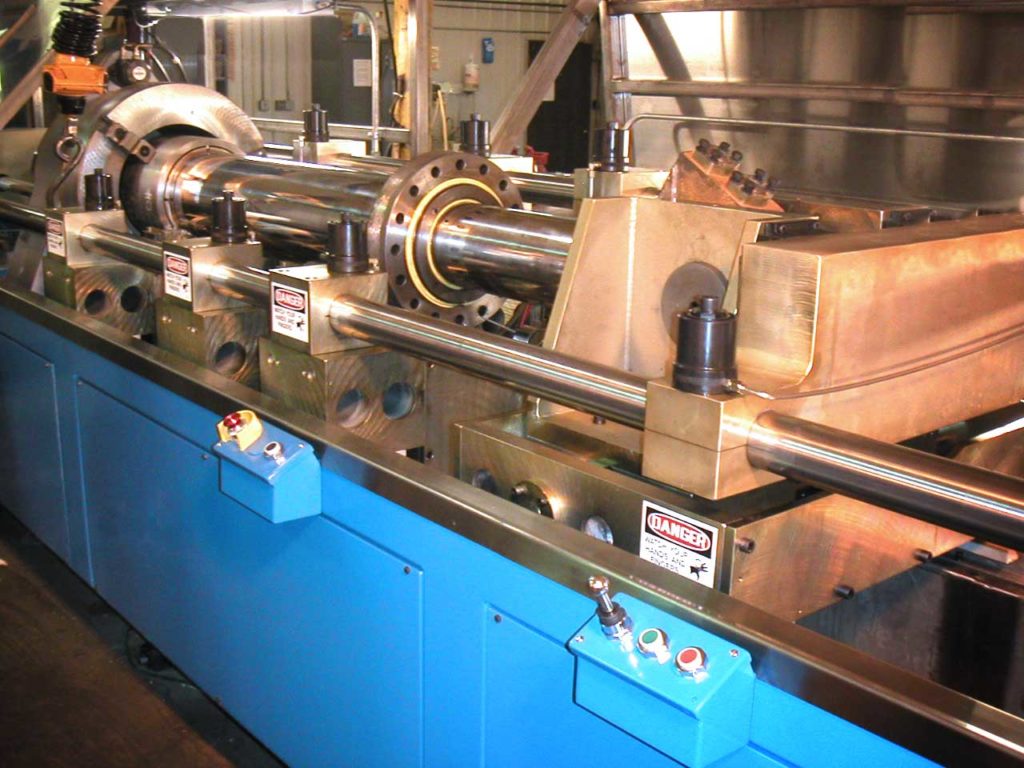

This facility is designed with two basic objectives. The first is to provide a safe and efficient means to assemble the cylinders. The computer control and data acquisitions ensured safety and quality in the assembly process. The cylinder is positioned horizontally for assembly and two-handed anti tie-down logic is used for all steps requiring movement. The second objective is to provide quick and accurate testing of the cylinders in a safe enclosed work area.

Both assembly and testing of the cylinder take place on the test area module. The rod end is the fixed position and opposite end is essentially an oversized chuck with special attachments.

After the assembly is complete, the operator connects the hoses to the test cylinder and is prompted to close the hood. The test procedure involves cycling the cylinders to purge the air, then blocking the appropriate ports to perform leakage (drift) tests. The leakage (drift) of the piston is measured using a Tempasonics position transducer. The fixture has a sliding clamping device attached to the position transducer. This allows the use of a short position transducer to increase the accuracy of the drift measurement.

All the necessary test parameters are controlled and all test variables are measured and recorded. Test procedures are stored on the test stand or data concentrator and can be recalled quickly to effect rapid model change in the production flow.

Project Details

DATE

2005

CLIENT

Catepillar

PROJECT TYPE

Cylinder